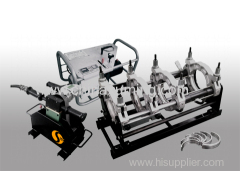

HDPE Electric Fusion Welder

1. Fuction:

Adjustable voltage (10-48V), can not be stored welding records, through manual input, you can also scan input (scanner optional) can be

divided into three welding, welding mode can be divided into voltage or current mode, the welding time to ambient

temperature compensation. Welding output voltage is automatically regulated in the setting of ± 0.3V.

2.How to use HDPE electrofusion welding machine:

Connect to the electrofusion welding machine, both sides need to plug welded PE pipe. Select the appropriate welding time, temperature and other parameters in the fused, and operate in accordance with the instructions on the fused machine. Fused different operating slightly different, not too complicated.

3.PE Electrofusion welding procedures

***Description:

1 LCD operation panel: can display operation prompt fault information and time parameters.

2 sliding scale button: or numeric characters plus a bonus one.

3 Decrease key: Digital minus 1 or impairment of a character.

4 Right key: cursor right one character.

5 Down keys: Move the cursor to the next line.

6 function keys: back to the main menu.

7 Enter key: After selecting a function and press Enter.

8 Start button: Start to welding operations.

9 emergency stop button: to force a quick stop welding process, interrupt the host to run.

10 Green indicator: normal fusion process is on, otherwise off.

11 red LEDs: power indicator.

12 Printer Interface: for connection to play should drive.

13 bar code input interface: for connecting barcode reader input.

14 power switch.

***Welding operation

Preparation before the operation, the fused pipe and pipe installation docking, the welder output plug fused pipe motor.

Power on, the display shows the main menu, press ↓ key to select a particular feature of the machine, press the Enter key to enter the submenu.

(1) Parameter setting function, select the item in the main menu settings (so the anti-color display), press Enter after entering the parameter setting menu, then you can set the welding parameters. Press ↓ to select one of the first to set a particular parameter, press → key to select a bit, press +, a key position of the cursor blinking modification. Welding time in seconds, cooling time in minutes. Printing press the + sign, display that opens the print function, then the welding process, the printer every five seconds and print a welding parameters, press - No. Close the print function.

(2) Welding run operation, after the machine parameters are set correctly, you can pipe welding operation, which selects the first five in the main menu, the "Run" key, then the machine displays the parameter settings confirmation after pressing the start button, the machine starts the welding operation.

(3) when the normal welding machine starts counting down from the preset time, when the display is 0000 When welding is completed, the machine will alarm. At this time, press any key, the machine automatically enters the cooling state after cooling is completed, the machine also alarm. At this point press any key to end the alarm and return to the main menu.

(4) When there is the way in which failure will automatically stop and display an error message. Where the current error, check the plug and pipe fittings to connect the output is good; voltage error, check the power supply voltage exceeds the 175-250V range; temperature error, check the temperature sensor is disconnected.

(5) To a second welding, just repeat the above process.

***Safety Precautions

Fused plug connector welded pipe must be solid and reliable, and definitely not loose.

Verification prior to welding the welding voltage, time, etc., and welding parameters are fused pipe with the consistent demand.

Must be in place when inserted into the pipe fittings, otherwise it will lead to weld failure.

Butt fused pipe fittings and pipe stress appear distorted or not allowed.

In the summer, the machine displays should avoid sun brunt.

Pay attention to moisture, water is prohibited inside the machine.