Products

- Gas Hose

- cpvc pressure pipes and fittings

- forged flanges

- ppr pipe fittings

- hdpe pipe fittings

- pp compression fittings

- wood plastic composite

- plastic pipe cutter

- garden tools

- pvc pipe fittings

- plastic pipe welding machine

- brass fittings

- pneumatic components

- sanitary hoses

- spray guns

- abs faucets

- brass bibcocks

- ball valves

- gate valves

- stop valves

- check valves

- fire valves

- garden valves

- boiler drain valves

- sanitary faucets

- Sanitary Ware

- pressure gauge

- others

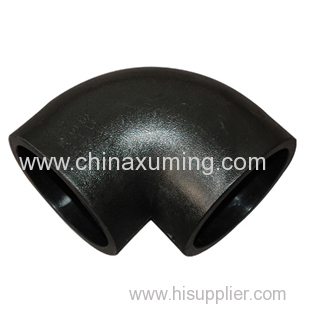

HDPE Socket Fusion 90 Degree Elbow Pipe Fittings

0.04~1.2 USD

Min. Order:

3000 Piece/Pieces

Trade Term:

FOB

Payment Terms:

L/C, T/T

Place of Origin:

Zhejiang, China (Mainland)

Means of Transport:

Ocean, Air

Production Capacity:

300000pcs/month

Packing:

carton

Delivery Date:

45 days

Head Code:

Others

Shape:

Equal

Technics:

Others

Type:

Elbow

Material:

HDPE80 or HDPE100

Connection:

Butt Fusion Injection

Brand Name:

OEM

Working Pressure:

SDR11,SDR17

Working Tempreture:

-40℃~40℃

Specifications:

DN20~DN110

Color:

Black

MOQ:

3000pcs per size

Working Life:

More than 50 years

Export Area:

All over the world

Port of Loading:

Ningbo or Shanghai